Process Development is a critical step to expedite the transfer of successful manufacturing processes into cGMP-compliant cleanroom suites. The 2,600 square foot Process Development Laboratory focuses on development, scale-up, and analytical testing of cell and cell-based biologics.

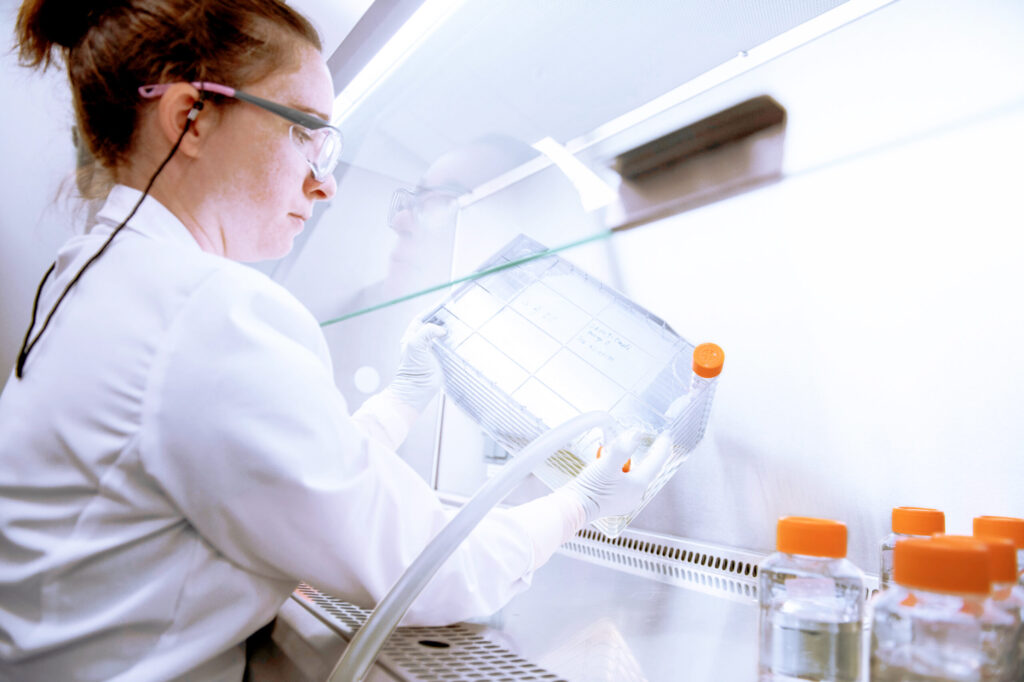

Experienced scientists lead technology transfer projects to ensure key process parameters are clearly defined, and critical quality attributes reproducibly meet specifications.

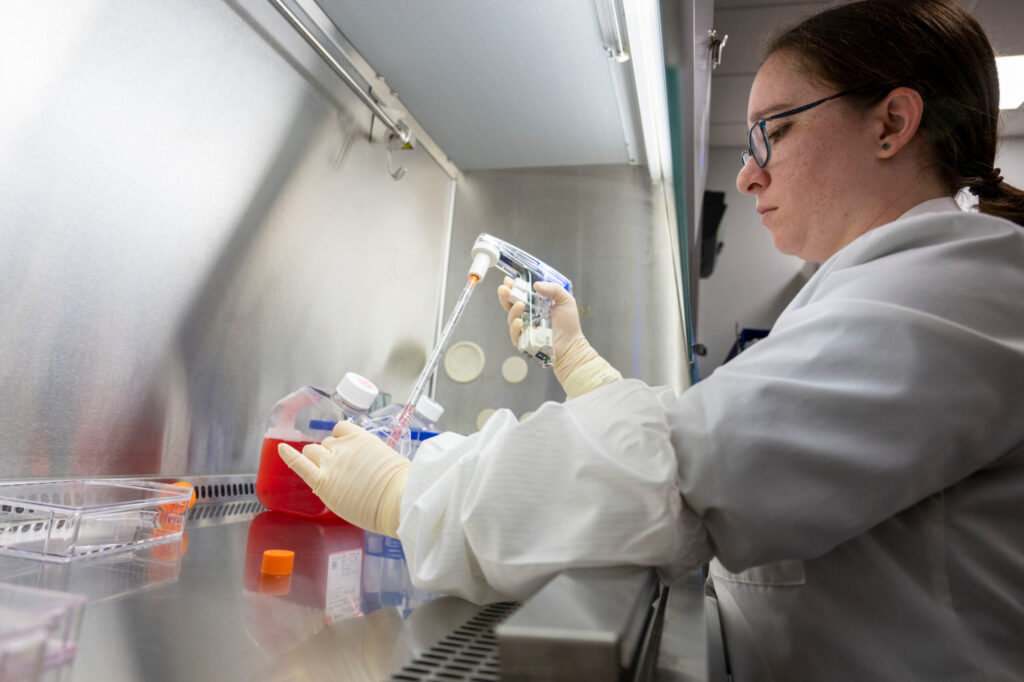

Process Development scientists utilize easily scalable unit operations to streamline scale up and tech transfer in both traditional static tissue culture plastic and bioreactor cell culture systems.

The Process Development Lab is equipped to perform Design of Experiments (DOE) studies to inform process improvements, then seamlessly scale the process. Additional services include identifying the materials and techniques needed to effectively scale-up and close a process so that it translates into clinical manufacturing.

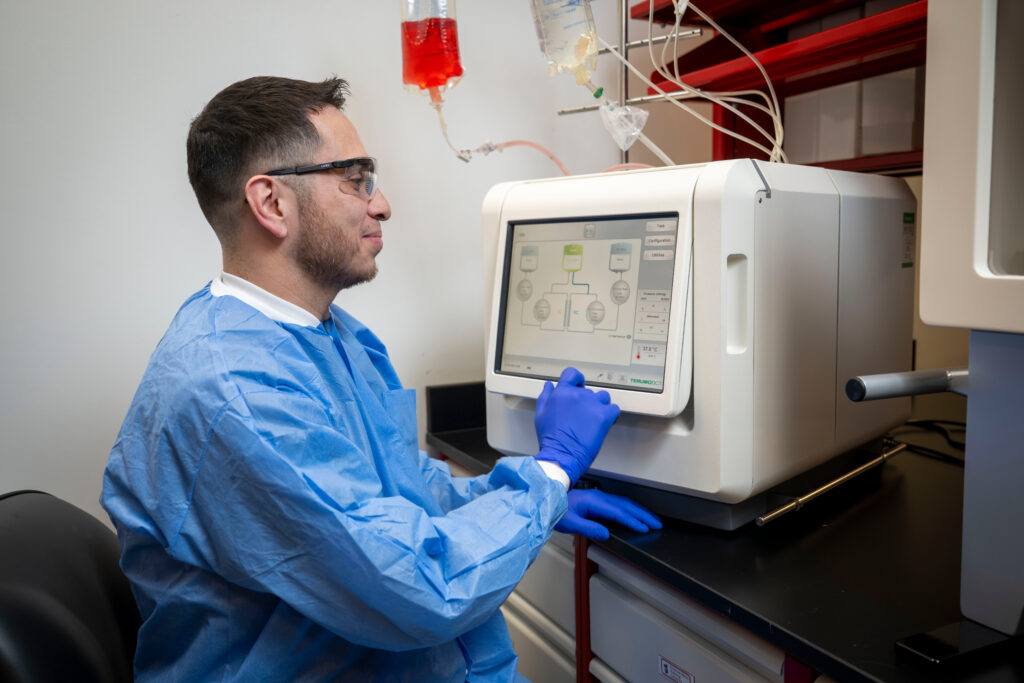

Using state-of-the-art analytical testing equipment, the Process Development team can identify key process parameters that will ensure manufacturing reproducibility.

The team helps clients identify appropriate advanced therapies manufacturing processes for optimal clinical batch production.

Process Development scientists ensure all aspects of a process are ready for cGMP manufacturing. Equipment is evaluated and qualified for appropriate applications and clinical production.

Process Development scientists draft complete batch records, including electronic batch records to provide streamlined post-production review and product release.

Starting materials and raw materials are verified to meet cGMP compliant specifications.

Training of cGMP cleanroom operators will be done by scientists who have developed, scaled up, and optimized manufacturing in the Process Development lab, maintaining consistency of manufacturing.